Jute: the challenges of a 100% natural raw material

Aug. 17, 2021

LC Packaging has been in de jute trade since 1923. Because jute is a natural crop, climate (and climate change) can have a big impact on its cultivation. While the popularity of jute as a material for consumer goods such as reusable shopping bags and applications in carpets and upholstery has grown tremendously, changes in weather patterns have had a negative impact on the availability of jute fibre in the recent past.

As a result, securing a constant flow of high quality jute and ultimately jute bags is a true juggling act. Especially with local lockdowns due to COVID-19. By closely monitoring such developments – together with our long-term production partners – we are able to adapt, respond and anticipate the long term. Based on close consultation with our customers regarding their anticipated volumes of jute bags, we have various long-term strategies in place.

The jute market at a glance

As circumstances may seem complex, let’s take a closer look at the developments in Bangladesh and India.

- Raw jute availability has been challenging. Last year, Cyclone Amphan severely impacted the jute harvest. Raw jute exports from Bangladesh amounted to 521.293 bales in July 2020-May 2021, against 710.903 bales during the same period one year earlier. [1]

- We can be optimistic about the future, as local governments are working hard to increase their output. Traditionally, jute growers from Bangladesh import 90% of their seeds from India as Bangladeshi farmers prefer to grow high-value vegetables instead of uncertified seeds for jute [2]. To increase jute production levels in Bangladesh, the Bangladeshi Government has launched a five-year plan to make Bangladesh self-sufficient in production of high quality jute seeds. This development will be implemented from this season onwards. In the next five years, 4,500 tonnes of jute seed should be produced and therefore a total of 8,780 hectares of land will be purchased for jute seed farming.[3] The Bangladesh Agricultural Development Corporation (BADC) will buy the seeds from the farmers [2].

- Imposed lockdowns in Bangladesh and India in April-July 2021 led to a lower attendance of workers in the mills and thus slower production [1]. In India, jute mills were closed temporarily due to shortage of raw materials and workers [2]. Today, production is on its way back to 100%.

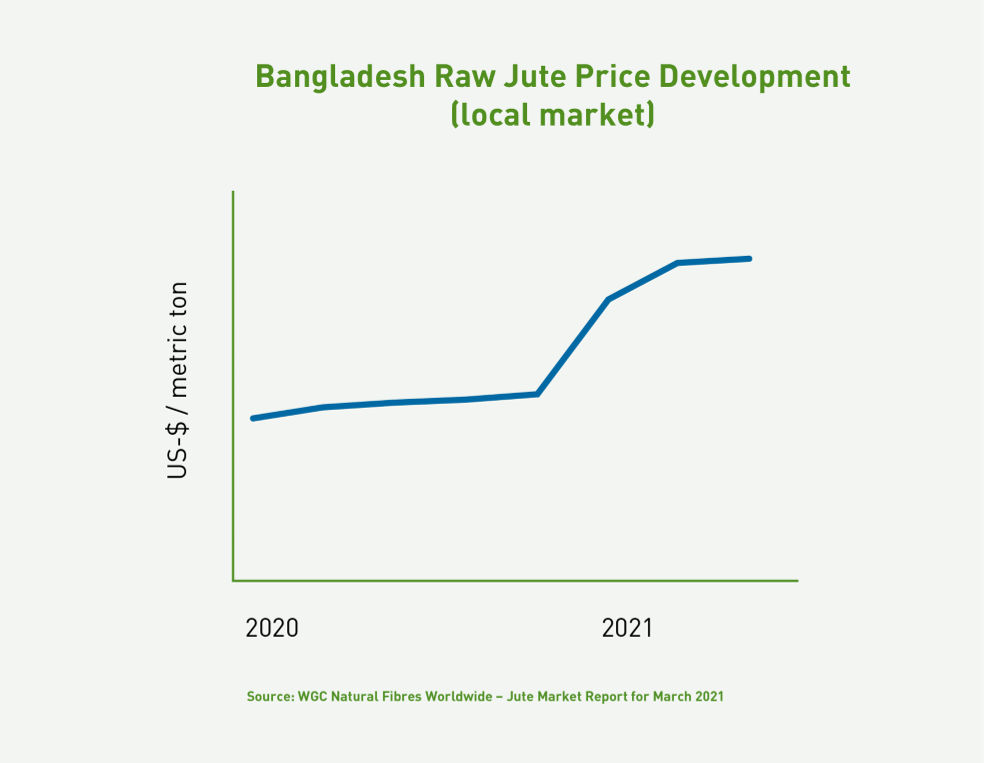

<< Article continues below the graph >>

Our customers depend on the specialists within LC Packaging who understand the jute market and the supply chain, who anticipate on market developments and are prepared for eventualities.

LC Packaging was able to amass sufficient stock and commitments of delivery to give our clients peace of mind. Current estimations show no major changes for the foreseeable future, although we continue to keep a close eye on global developments.

Sources

[1] WGC Natural Fibres Worldwide – Jute Market Report for July 2021, 2 August 2021

[2] WGC Natural Fibres Worldwide – Jute Market Report for May 2021, 2 June 2021

[3] WGC Natural Fibres Worldwide – Jute Market Report for January 2021, 4 February 2021