30% Recycled Content in LC Packaging FIBCs

16 Maj 2022

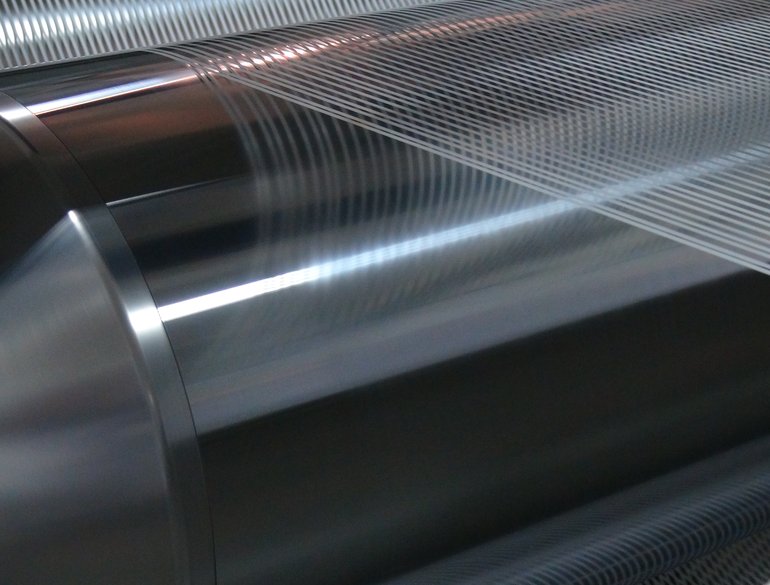

LC Packaging is happy to announce that its own production facility Dutch-Bangla Pack Ltd. (DBPL) and our key production partners are now able to produce FIBCs (big bags) with 30% recycled content. This has been achieved without having to increase the weight of the fabric, and the FIBCs remain as strong and safe as a bag from virgin material! The 30% can be achieved with both Post-Industrial recyclate (PIR) and Post-Consumer recyclate (PCR) materials.

30% rPP big bag

At LC Packaging, we strive to do things ‘the right way’. Over the past year or so, LC Packaging has been working together with its key production partners on producing high-quality FIBCs with recycled content. Research, testing showed a need for investments in new machineries and adjusting the setup of existing machinery. With these investments and changes made, we can confidently stand behind our claim and offer customers 30% rPP big bags. To further ensure credibility we are now looking together with the production partners at external certification.

What’s next?

Of course, there are still challenges to be faced. In today’s market there is a limit of the amount of rPP available, and as of now not all production lines can produce rPP. Investments for future expansion of production capacity and finding new ways to obtain rPP material are high on the agenda.

Customers are encouraged to contact their local account manager to discuss the possibilities of rPP packaging for their products.

Post-Industrial vs Post-Consumer

In rPP material, we distinguish between rPP from post-industrial recyclate (PIR) and post-consumer recyclate (PCR). Post Industrial recyclate (PIR-rpp) is the recycling of material waste created during the manufacturing processes. In FIBC production we refer to this as process waste. This material is generally of better quality, and can be carefully sorted to get white colors. Post-consumer recyclate (PCR-rPP) is material that has been made from FIBCs that have been actually used, sorted, collected, cleaned and recycled into new rPP granules. To ensure that the bag will not break and eliminate the risk of contamination toward the product, the quality of the PCR is extremely important. It is therefore important to be very careful and price in handling and using PCR-rPP. This is one of the reasons for the extensive testing done over the past year.

Many countries are introducing taxes and producer responsibility schemes. Post Industrial recyclate is considered to be recycled material for the purpose of the UK Plastic Packaging Tax but will not count for most other such schemes. Only FIBCs produced from post-consumer recyclate will count as real recycled material. Members of voluntary commitments such as the Plastic Pact also won’t count this as recycled material. It is therefore important to be precise.