UN Big Bags

Are you looking to transport your hazardous goods safely? Our UN Big Bags (FIBCs, Jumbo Bags) are certified for the transport of hazardous materials (HAZMAT) under ADR regulations. The Big Bags are tested and designed to comply with all the requirements of a UN FIBC to keep your product safe during transportation.

Benefit from our UN Big Bags

- Certified to transport hazardous goods

- Available in flat woven or tubular woven fabric

- Various lifting possibilities available

- UN code available upon request

UN directives

The transport of hazardous goods is regulated worldwide by a Subcommittee of Experts on the Transport of Dangerous Goods of the United Nations Economic and Social Council (ECOSOC). They form the basis of several international agreements and many national laws. They have issued recommendations on the transport of dangerous goods to protect public health and prevent accidents, injuries and damage to property and pollution.

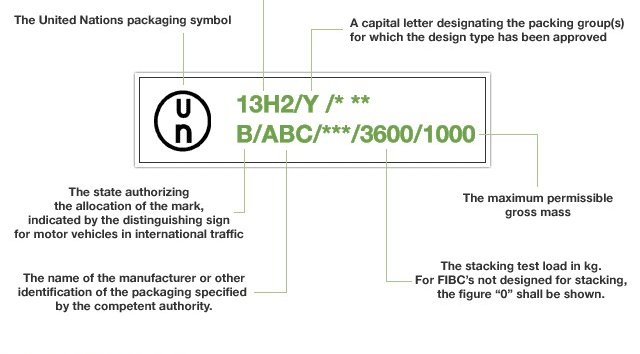

In our own test facilities we design and test your Big Bags (FIBCs) according to all requirements set by the UN. The FIBCs are then officially certified by repeating the tests in an independent testing facility. Based on both test results, a unique UN number is issued for your FIBC.

Dangerous goods

Dangerous (hazardous) products are classified by the United Nations with a unique UN product number. These product numbers and corresponding packaging group classifications can be found in the ‘orange book’.

| Degree of Danger | Packing Group | UN Symbol | Max. Volume |

|---|---|---|---|

| High* | | | X | 1.5 m³ |

| Medium | || | Y | 3 m³ |

| Low | ||| | Z | 3 m³ |

*Packing group I (with degree of danger ‘high’) is not applicable for FIBCs

There are four types of Big Bags made from woven plastics that can be used to pack/transport hazardous goods:

13H1: woven PP without coating and without liner

13H2: woven PP, coated and without liner

13H3: woven PP, uncoated and with liner

13H4: woven PP, coated and with liner

The symbols below are used for the maximum permitted stacking weight or to indicate that stacking is not permitted.

UN Big Bags testing

A UN Big Bag is subjected to thorough testing to guarantee its safety and integrity under conditions of intended use and the protection of your valuable product. Namely:

| Top lift test | The Big Bag is loaded with six times the maximum load. |

|---|---|

| Drop test | Depending on the packaging group, the Big Bag filled with the maximum load is dropped in an upright position from a height of 80 or 120 cm. |

| Topple test | Depending on the packaging group, the Big Bag filled with the maximum load is toppled from a height of 80 cm or 120 cm. |

| Righting test | After being toppled, the Big Bag filled with the maximum load is lifted to an upright position using one or two of its loops. |

| Tear test | A 100 mm tear is made on one of the sides of the Big Bag filled with the maximum load. The Big Bag is then filled with twice its maximum load for a minimum of five minutes. Finally, the Big Bag is suspended with its SWL for another five minutes. |

| Stacking test | The Big Bag filled with the maximum load is loaded with 1.8 times the weight that is permitted on top of the Big Bag. |

Key industries

Key industries

Contact

Bring us your challenge!

Supporting your products is what we do at LC Packaging. We offer you safe, reliable and qualitative transport packaging for your valuable products. You can benefit from our international network and take advantage of all available expertise at LC Packaging. Our packaging experts are ready to help you find the best flexible packaging solution for your products.